600L Complete Grain Whisky Distillery Equipment

- Sep 27, 2025

- 135

- tiantai

Product Description

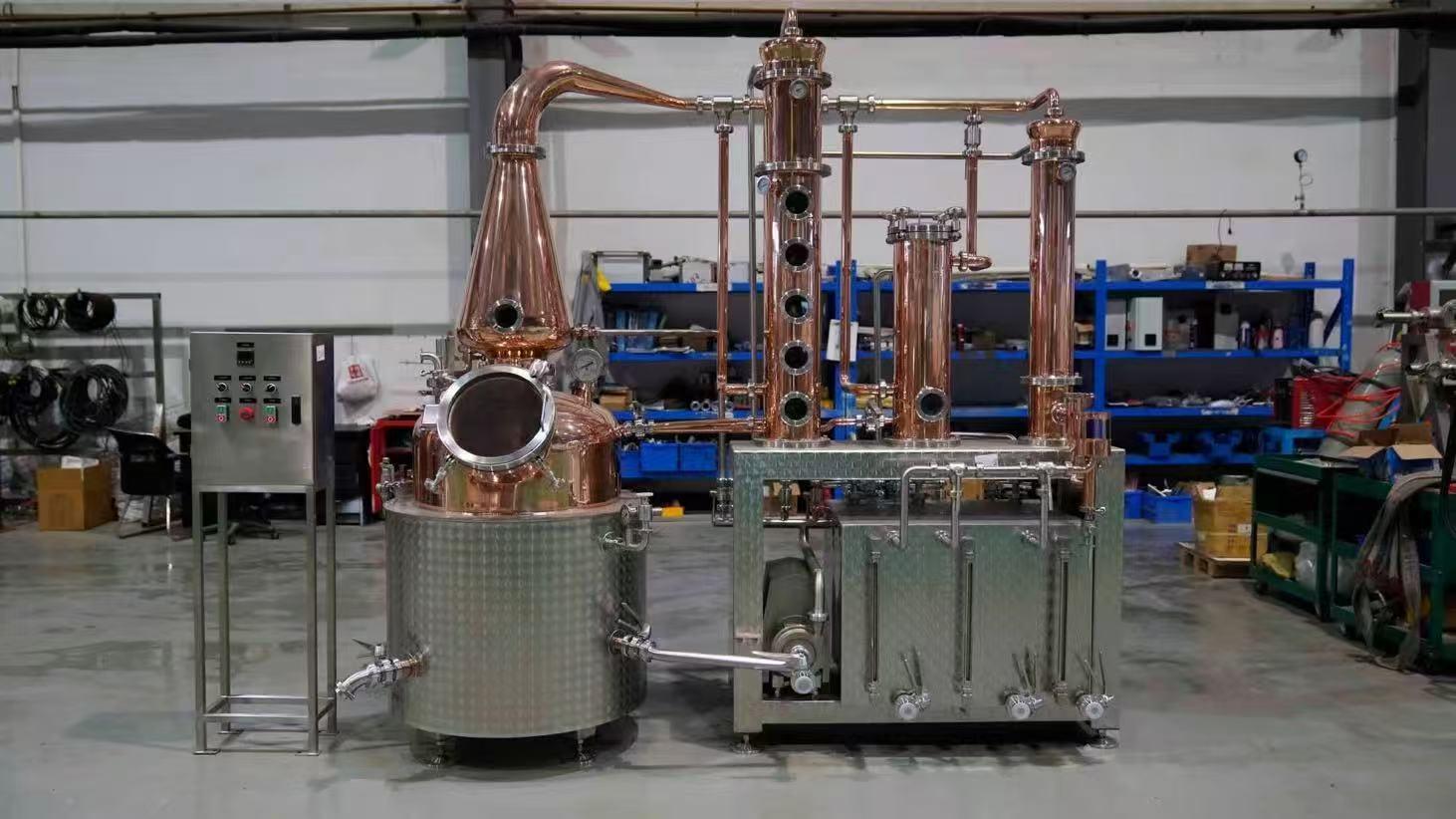

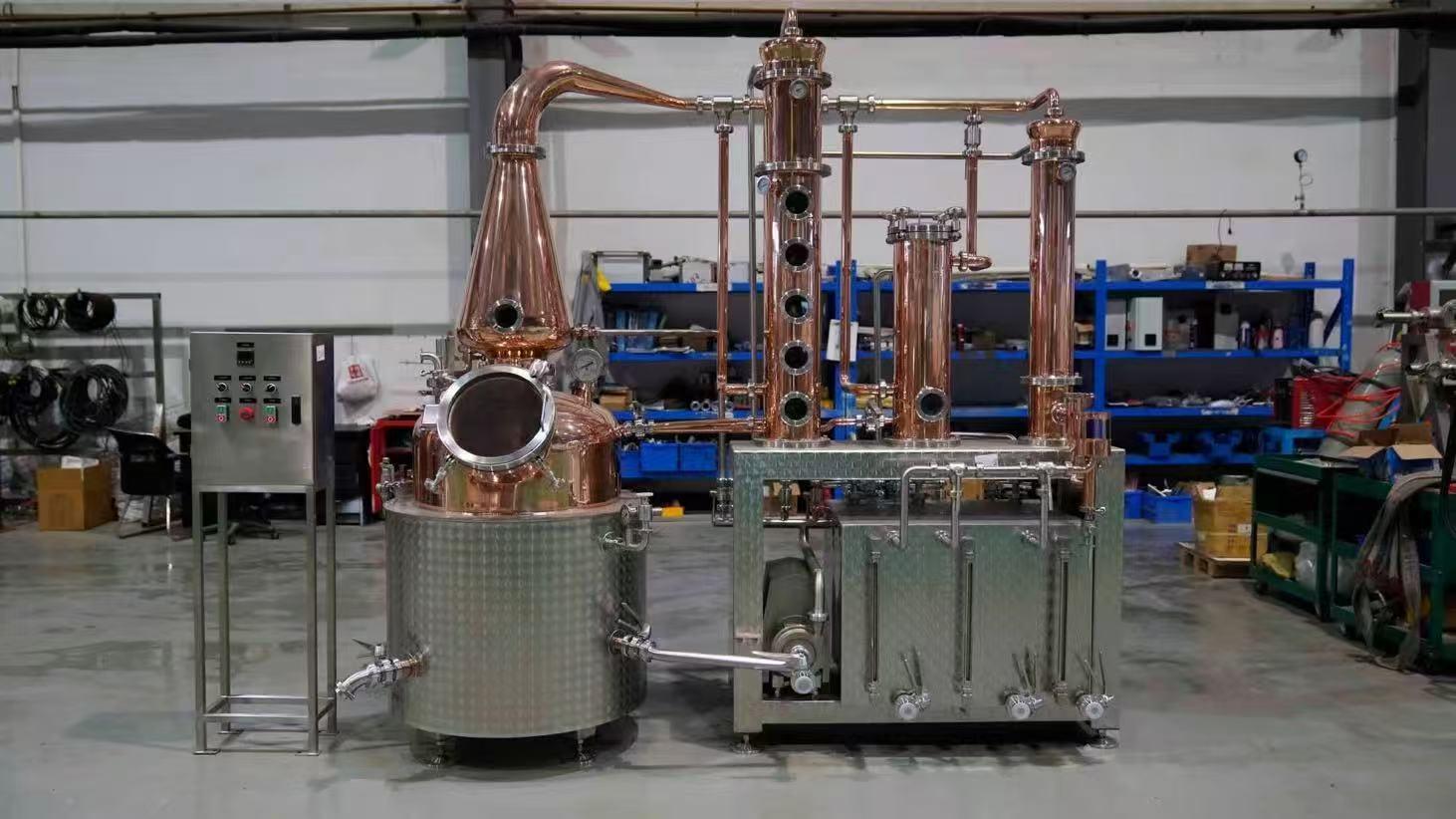

The 600L Complete Grain Whisky Distillery Equipment is a fully integrated production line designed for professional whisky production. Unlike single malt whisky systems with double pot stills, this system adopts a column still combined with a copper pot still, making it ideal for grain whisky production with higher efficiency and lighter spirit profiles.

This complete set includes malt milling, brewhouse, fermentation, glycol cooling, distillation, CIP cleaning, and control systems, ensuring smooth operation and compliance with food-grade sanitary standards. It is suitable for small-to-medium distilleries looking to scale production with consistent quality.

Key Features

-Complete system from milling to bottling

-600L brewhouse with sanitary pumps and heat exchanger

-4x600L jacketed fermenters with glycol cooling

-Copper pot still + column distillation for whisky production

-Gin basket included for flavoring versatility

-Portable CIP cart for efficient cleaning and sanitation

-Semi-automatic control cabinet for precise operation

-Built with food-grade stainless steel and copper

-Optional pipeline instrument sensors available

Specifications

Packing&Shipping

Before delivery, all of tanks and accessories included in beer brewery equipment will be packed with PE films and frame.

During loading, tanks will be wired with iron wire and bolt to fix them inside container. After delivery, loading drawing will be provided to customer for learning loading layout.

Company information

Shandong Tiantai Beer Equipment Co., Ltd. is a professional manufacturer and engineering solution provider specialized in brewing equipment. Since our establishment in 2012, we have focused on the R&D and manufacturing of craft beer brewing systems, offering complete solutions for mashing, fermentation, filling, and CIP. Our systems support brewery and workshop projects of 50 liters and above.

In recent years, we have continuously expanded our product lines to include distillation equipment (suitable for whisky, vodka, gin, etc.), kombucha fermentation systems, fruit wine brewing equipment, low-temperature fermentation units, and multi-purpose stainless steel tanks for storage, mixing, or chilling. These products are widely used across beverage, fermentation, and biopharmaceutical industries.

With a team of experienced engineers, we offer customized designs and tailored solutions. Whether you're looking for a complete brewing system or a single sanitary-grade stainless steel tank, feel free to contact us — we are committed to delivering one-stop solutions and reliable equipment support.

The 600L Complete Grain Whisky Distillery Equipment is a fully integrated production line designed for professional whisky production. Unlike single malt whisky systems with double pot stills, this system adopts a column still combined with a copper pot still, making it ideal for grain whisky production with higher efficiency and lighter spirit profiles.

This complete set includes malt milling, brewhouse, fermentation, glycol cooling, distillation, CIP cleaning, and control systems, ensuring smooth operation and compliance with food-grade sanitary standards. It is suitable for small-to-medium distilleries looking to scale production with consistent quality.

Key Features

-Complete system from milling to bottling

-600L brewhouse with sanitary pumps and heat exchanger

-4x600L jacketed fermenters with glycol cooling

-Copper pot still + column distillation for whisky production

-Gin basket included for flavoring versatility

-Portable CIP cart for efficient cleaning and sanitation

-Semi-automatic control cabinet for precise operation

-Built with food-grade stainless steel and copper

-Optional pipeline instrument sensors available

Specifications

| Equipment Module | Core Configuration | Key Parameters |

| 1. Malt Crushing Unit | Malt Miller (Model: JMF-3A-15) | Capacity: 300-500kg/hr, double chrome-plated steel rollers (Φ155x200mm), 1.5kw motor, 80L hopper |

| 2. 600L Brewhouse System | Mash/Lauter Tun | Volume: 600L (with ≥25% headspace), material: SUS304, heating method: steam, wedge-shaped filter plate, equipped with grain rake |

| Hot Water Tank (HLT) | Volume: 600L (with ≥15% headspace), material: SUS304, heating method: steam, floating ball level sensor with alarm | |

| Auxiliary Parts | Stainless steel work platform (with non-slip floor), 2 sanitary centrifugal pumps (3M³/Hr), sanitary pipes/valves | |

| 3. Fermentation Unit | Fermentation Tanks (4 sets) | Single tank volume: 600L (with ≥25% headspace), material: SUS304, cooling method: glycol (-5℃), conical bottom |

| Auxiliary Parts | Dry hopping port, sanitary sampling valve, pressure safety valve (2bar) | |

| 4. Glycol Cooling Unit | Glycol Water Tank | Volume: 1200L, material: SUS304, insulation thickness: 80mm |

|

Glycol Chillers (2 sets) |

Type: 3P air-cooled, cooling capacity: 9100W, outlet temp.: -5℃, refrigerant: R407C (environmentally friendly) | |

| Circulation System | 1 glycol water pump (4M³/Hr), insulated PPR pipes, 6 temperature control points | |

| 5. Distillation Unit | Copper Still Pot | Volume: 600L, inner material: TP2 red copper, heating power: 45KW electric (steam optional), equipped with agitator |

| Distillation Auxiliaries | Copper swan neck & lyne arm, 4-tray bubble-cap distillation column, gin basket, shell-and-tube condenser, 3 spirit receiver tanks (100L+150L+200L) | |

| 6. 100L Portable CIP Cart | Caustic/Acid Tanks (2 sets) | Single tank volume: 100L, material: SUS304, caustic tank with 6KW electric heating |

| Auxiliary Parts | 1 sanitary CIP pump (3M³/Hr), stainless steel portable trolley, independent control cabinet | |

| 7. Electric Control Unit | Main Control Cabinet | Controls brewhouse, fermenters & glycol system; includes VFD for speed adjustment (pump/agitator), temperature display & auto-control; brand electrical components (Schneider/ABB, etc.) |

| 8. Spare Parts & Tools | Standard Spare Parts Kit | Sanitary hoses, pump seals, temperature sensors, wrenches/measuring tools (for installation & maintenance) |

Packing&Shipping

Before delivery, all of tanks and accessories included in beer brewery equipment will be packed with PE films and frame.

During loading, tanks will be wired with iron wire and bolt to fix them inside container. After delivery, loading drawing will be provided to customer for learning loading layout.

Company information

Shandong Tiantai Beer Equipment Co., Ltd. is a professional manufacturer and engineering solution provider specialized in brewing equipment. Since our establishment in 2012, we have focused on the R&D and manufacturing of craft beer brewing systems, offering complete solutions for mashing, fermentation, filling, and CIP. Our systems support brewery and workshop projects of 50 liters and above.

In recent years, we have continuously expanded our product lines to include distillation equipment (suitable for whisky, vodka, gin, etc.), kombucha fermentation systems, fruit wine brewing equipment, low-temperature fermentation units, and multi-purpose stainless steel tanks for storage, mixing, or chilling. These products are widely used across beverage, fermentation, and biopharmaceutical industries.

With a team of experienced engineers, we offer customized designs and tailored solutions. Whether you're looking for a complete brewing system or a single sanitary-grade stainless steel tank, feel free to contact us — we are committed to delivering one-stop solutions and reliable equipment support.