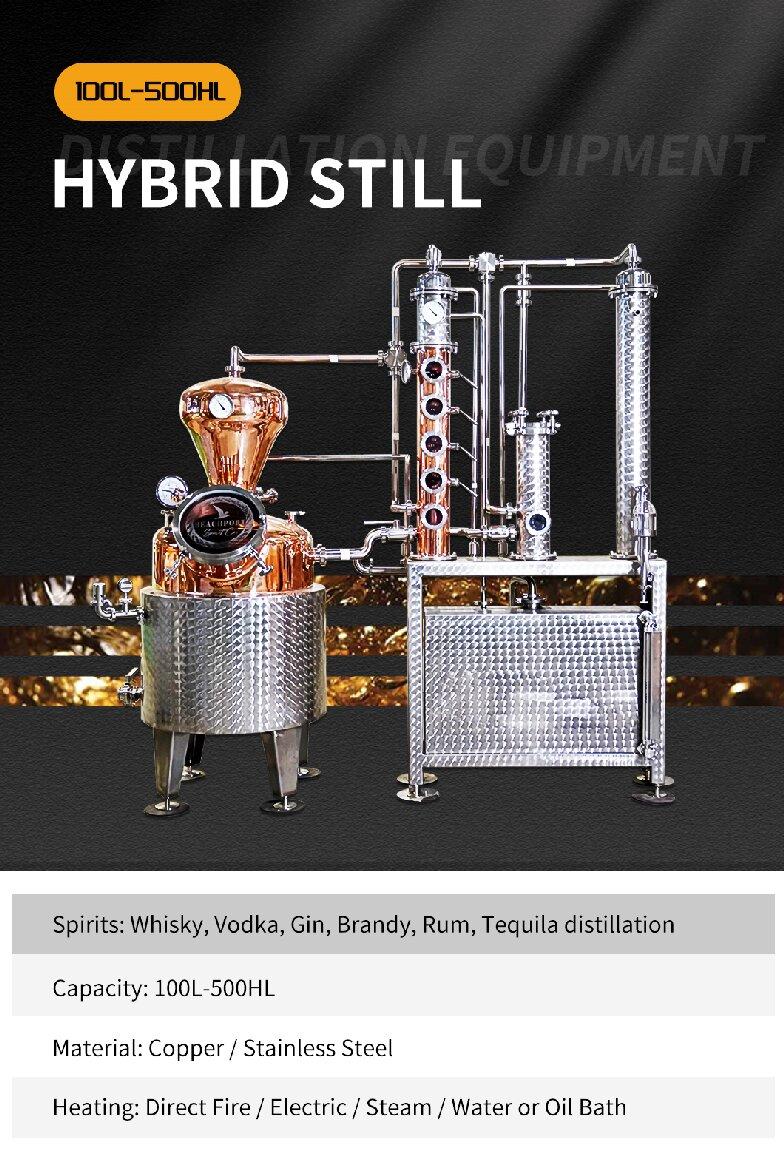

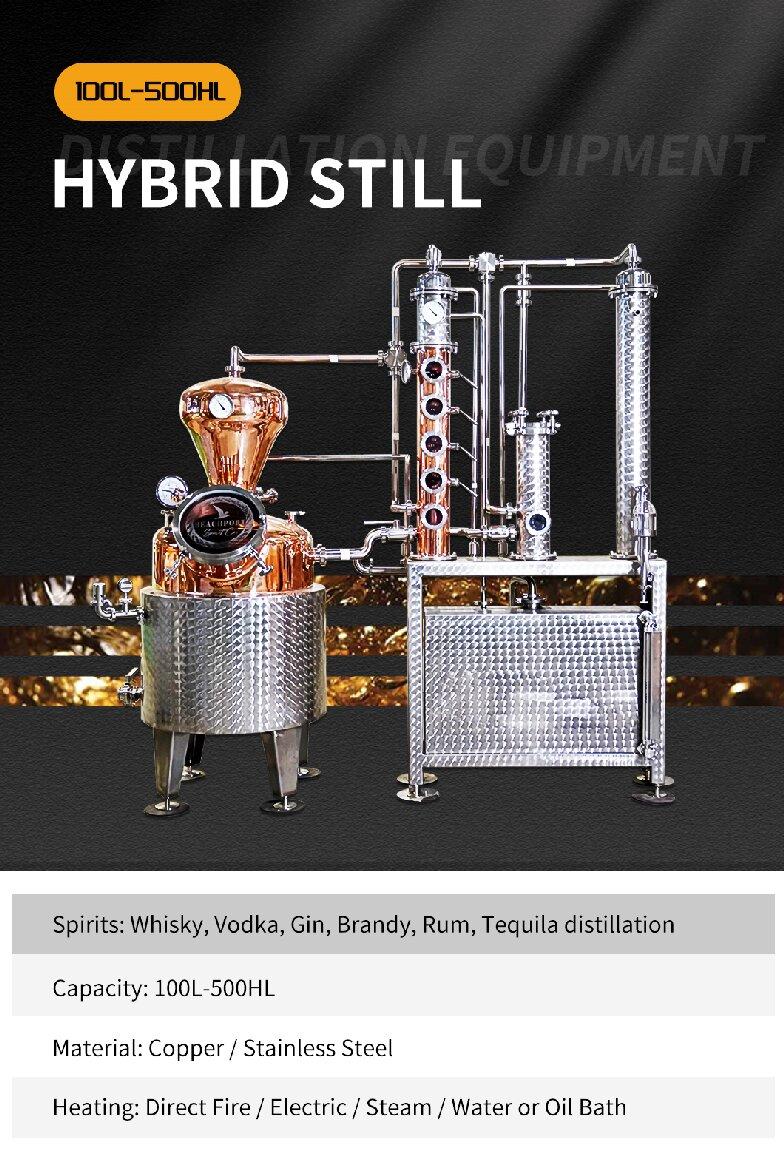

200L Copper Still Alcohol Distillation Unit

- Jul 22, 2025

- 54

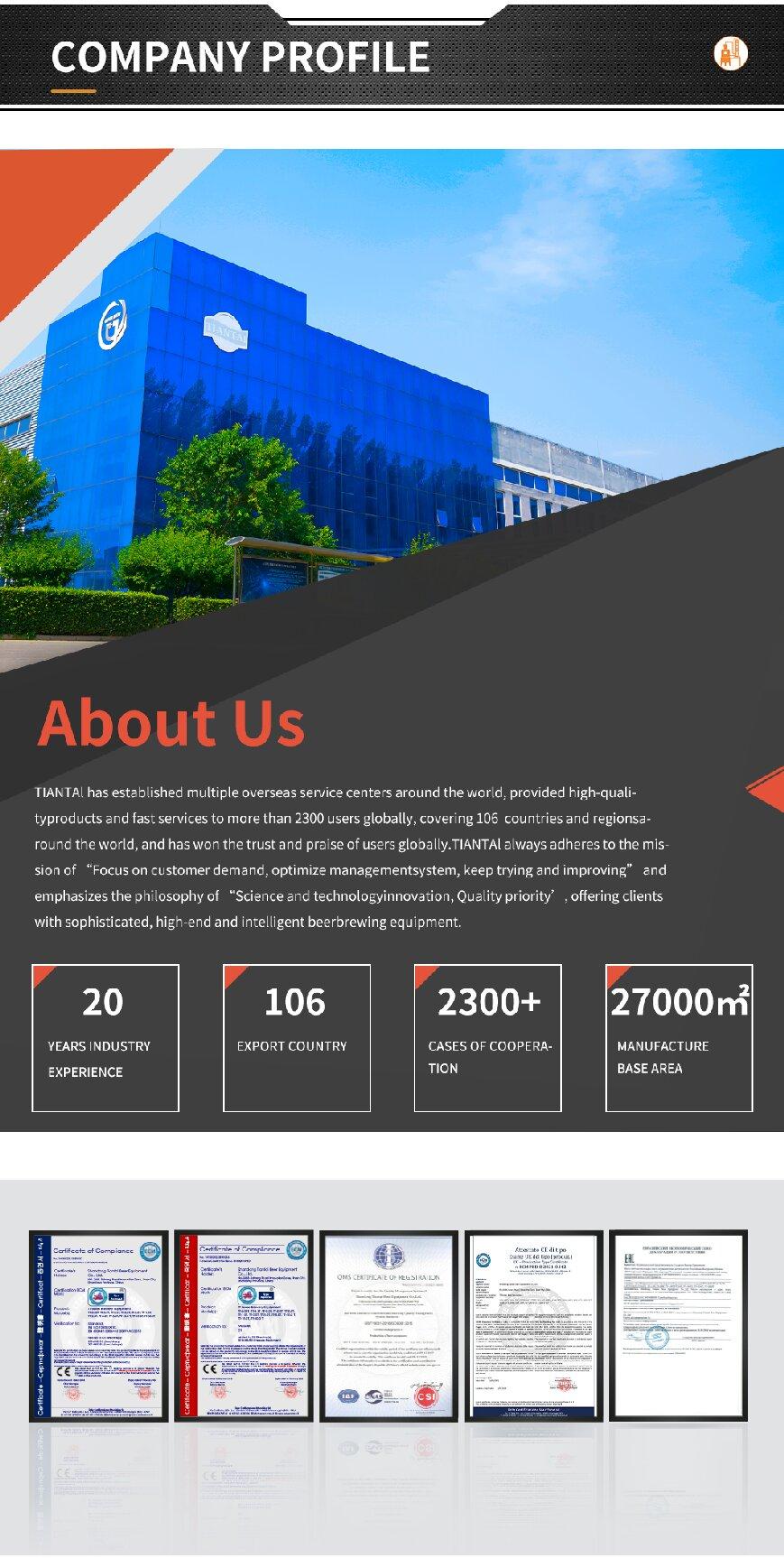

- tiantai

Product Overview

Our 200L distillation unit offers a significant upgrade in capacity, making it suitable for micro-distilleries and growing craft spirit brands. With flexible heating options and a copper column design, it’s a perfect solution for producing high-quality gin, whiskey, rum, and more.

Technical Specifications of 200L Alcohol Distillation Equipment

Key Features

**Polished stainless steel boiler with copper column

**Bubble cap or sieve plate column (custom options)

**Dephlegmator with sight glasses for high-proof control

**Parrot outlet with spirit strength monitoring

**Built-in CIP system for easy cleaning

**Pressure gauges & safety valve included

**Custom control panel (manual or semi-automatic)

Perfect For

Craft distillers & spirit startups

Pilot testing & product development

Hospitality & boutique beverage brands

Educational or research facilities

Optional Auxiliary equipment in 200L Alcohol Distillation Equipment

To ensure efficient and continuous operation of the distillation system, the following auxiliary equipment can be included as part of the complete solution:

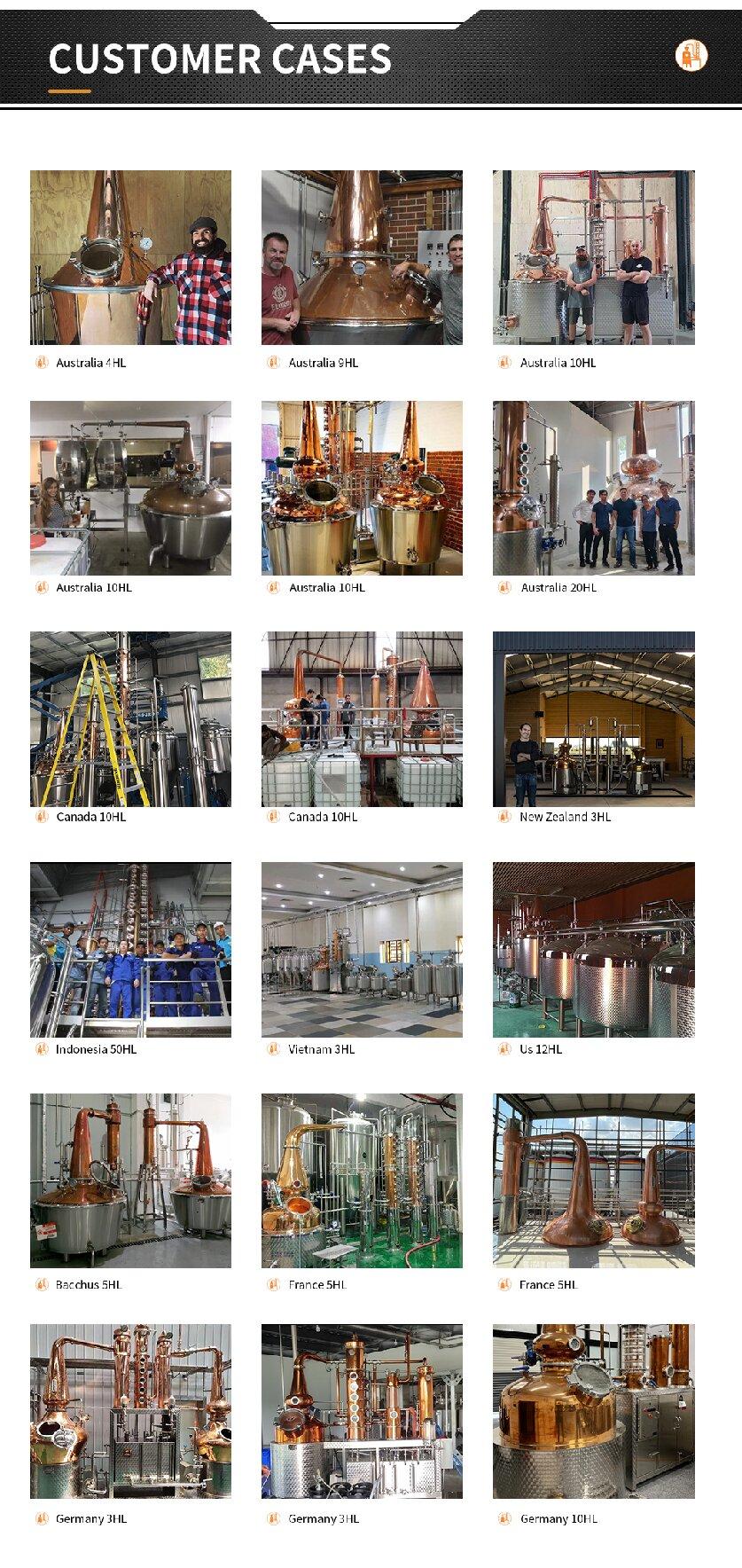

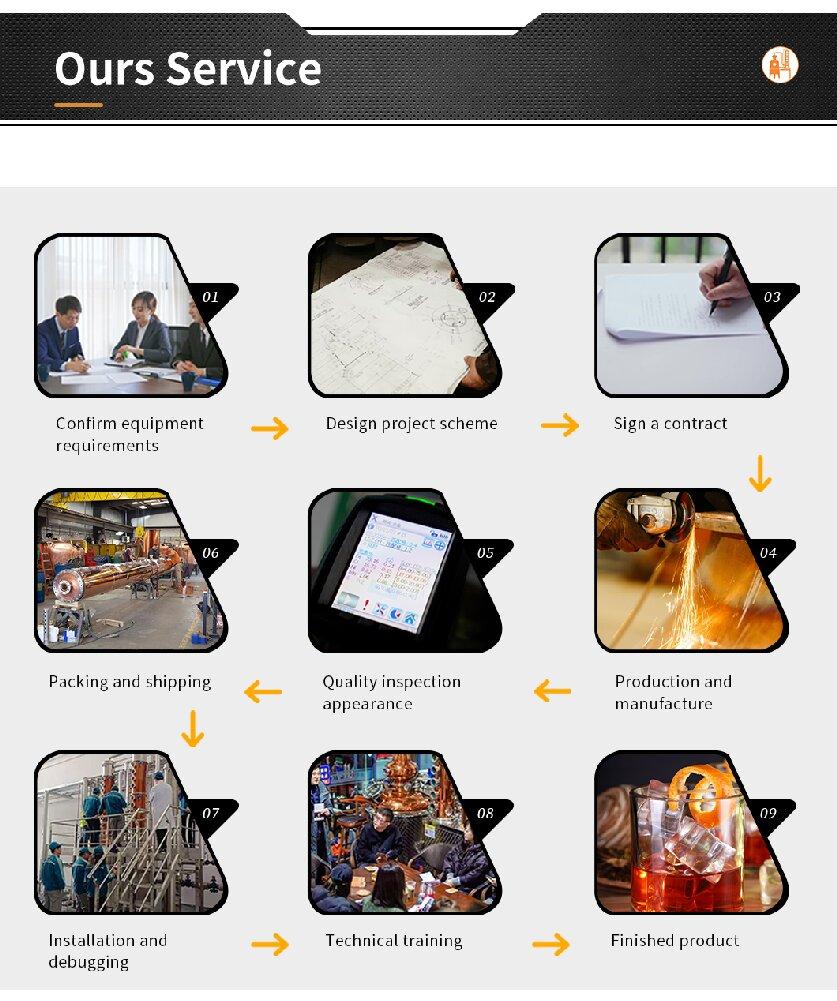

Packaging & Delivery

Export-grade packaging (wooden case)

CE / ISO / SGS compliant

Lead time: [40-50 working days]

Worldwide shipping with DDP available

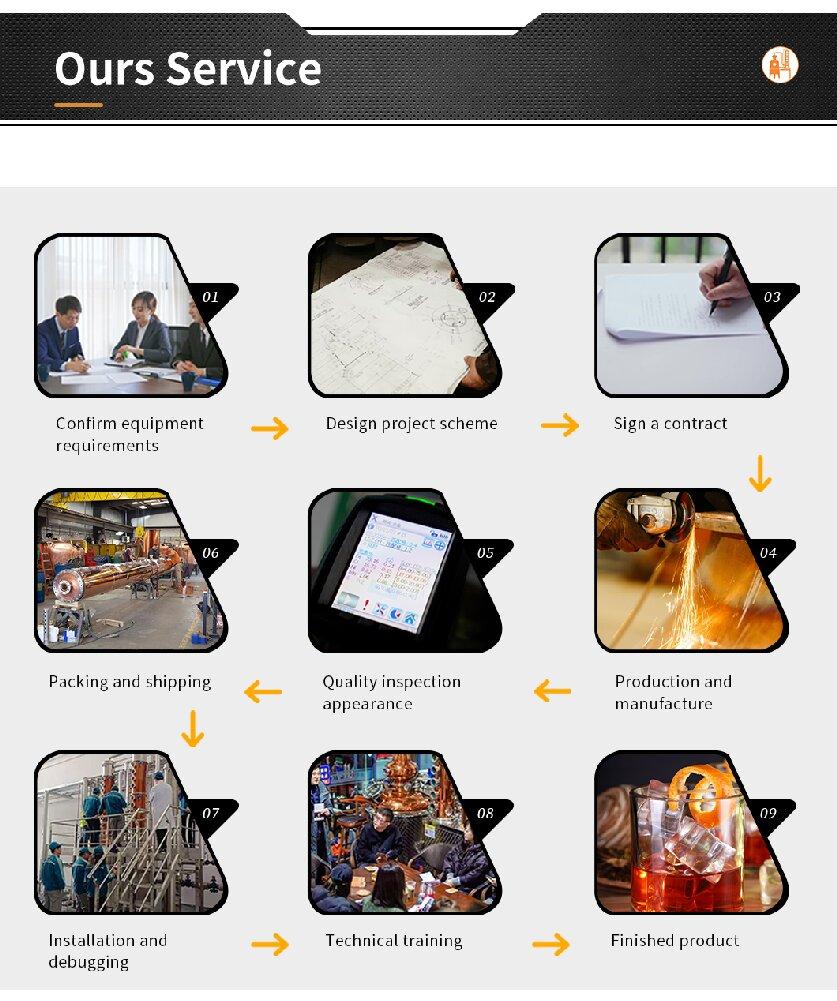

Why Choose Our 200L Alcohol Distillation Equipment?

* One machine, multiple functions

* Built for quality, flexibility, and scalability

* Customizable layout and distilling technology

* Expert support for installation and training

Need Help Choosing the Right Size?

Contact us to get expert support and layout advice — we’ll help you select the perfect system for your production needs.

Let’s build your distillery dream together!

Our 200L distillation unit offers a significant upgrade in capacity, making it suitable for micro-distilleries and growing craft spirit brands. With flexible heating options and a copper column design, it’s a perfect solution for producing high-quality gin, whiskey, rum, and more.

Technical Specifications of 200L Alcohol Distillation Equipment

| Item | Technical Specification |

| Effective Volume | 200 Liters |

| Daily Output Approx | 20–40 Litres |

| Heating Method | Electric / Steam (optional) |

| Power Supply | 220V / 380V / Custom |

| Still Pot | Interior Shell: TP2 Red Copper; Exterior Shell: SUS304 stainless steel; Steam Heated |

| Helmet | TP2 Red Copper |

| Swan Neck and Lyne Arm | TP2 Red Copper |

| Dephlegmator | 304 Stainless steel (TP2 Red Copper is optional) |

| Distill Column | TP2 Red Copper, 4 Trays (Customized) |

| Gin Basket | 304 Stainless steel (TP2 Red Copper is optional) |

| Condensor | 304 Stainless steel (TP2 Red Copper is optional) |

| Parrot Outlet | 304 Stainless steel (TP2 Red Copper is optional) |

| Alcohol Vapor Pipeline&Valves | 304 Stainless steel (TP2 Red Copper is optional) |

| CIP Pipeline & Valves | 304 Stainless steel |

| Supporting Frame | 304 Stainless steel |

| Control Cabinet | Instrumental Control Panel (PLC is optional) |

| Spirit Receiver Tanks | 304 Stainless steel Foreshots head, Middle cut and Feints Receiver Tank |

Key Features

**Polished stainless steel boiler with copper column

**Bubble cap or sieve plate column (custom options)

**Dephlegmator with sight glasses for high-proof control

**Parrot outlet with spirit strength monitoring

**Built-in CIP system for easy cleaning

**Pressure gauges & safety valve included

**Custom control panel (manual or semi-automatic)

Perfect For

Craft distillers & spirit startups

Pilot testing & product development

Hospitality & boutique beverage brands

Educational or research facilities

Optional Auxiliary equipment in 200L Alcohol Distillation Equipment

To ensure efficient and continuous operation of the distillation system, the following auxiliary equipment can be included as part of the complete solution:

| Equipment Name | Description |

| Mill | Crushing Malt, Raw Grain etc |

| Mash tun or Mash/Lauter tun | Malt/Grain Mashing and Lautering |

| Hot Water Tank | Supplying Hot Water for Mashing, Sparging, Cleaning etc |

| Cold Water Tank | Supplying Cold Water for Wort Cooling, Beer Cooling, Distilling etc |

| Fermentation Tank | Fermenting wort/wash |

| Glycol Water Tank | Cooling Cold Water and Beer etc |

| Glycol Chiller | Chilling Glycol Water |

| CIP |

Cleaning |

Packaging & Delivery

Export-grade packaging (wooden case)

CE / ISO / SGS compliant

Lead time: [40-50 working days]

Worldwide shipping with DDP available

Why Choose Our 200L Alcohol Distillation Equipment?

* One machine, multiple functions

* Built for quality, flexibility, and scalability

* Customizable layout and distilling technology

* Expert support for installation and training

Need Help Choosing the Right Size?

Contact us to get expert support and layout advice — we’ll help you select the perfect system for your production needs.

Let’s build your distillery dream together!

Edited by Nicole

Sales manager of Tiantai brewtech

Email: [email protected]

Sales manager of Tiantai brewtech

Email: [email protected]