6000L Complete Single Malt Whisky Distillation System

- Aug 29, 2025

- 74

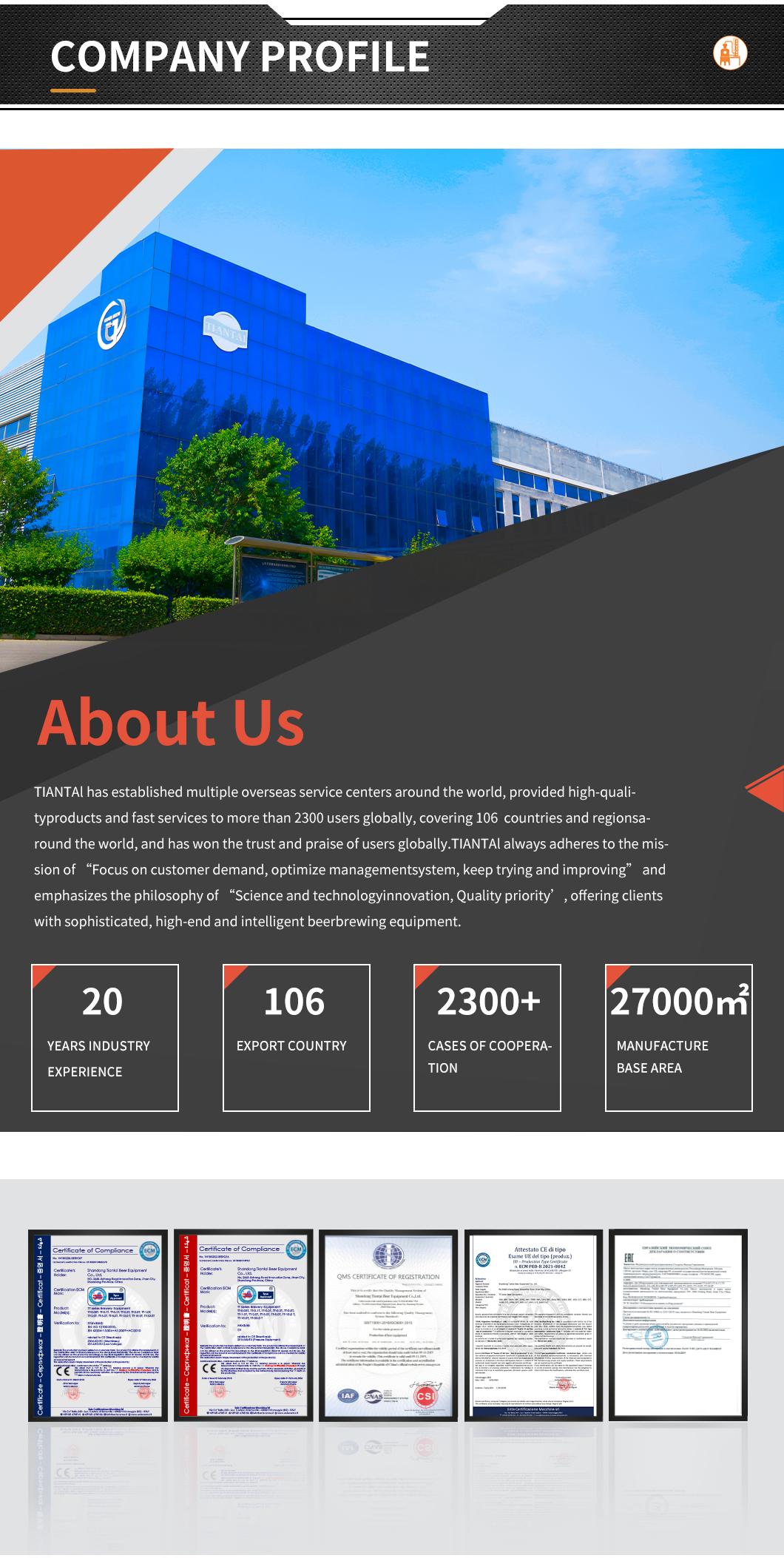

- tiantai

I. Brife Introduction of Single Malt Whisky Distillation System

Single Malt Whisky is a premium spirit made exclusively from malted barley at a single distillery, using traditional distillation methods. Renowned for its rich, complex flavors and smooth character, each batch reflects the unique influence of the distillery’s location, water source, and aging in oak casks. Connoisseurs and whisky enthusiasts can enjoy delicate notes of malt, vanilla, fruit, and subtle smoke, offering a refined and memorable tasting experience.

To help distillers craft high-quality single malt whisky, Tiantai Distillation System is designed for both craft and commercial distilleries, combining traditional craftsmanship with modern technology. The distillation system includes miller, mash/lauter tun, fermentation tanks, and copper pot stills or distillation columns, equipped with premium condensers and spirit collection devices to ensure optimal alcohol purity and flavor retention. Whether for small-batch or large-scale production, Tiantai distilling equipment enables distillers to consistently produce single malt whisky with unique character and exceptional quality.

Here, let us talk about 6000L Complete Single Malt Whisky Distillation System in details.

II. Key Configuration of 6000L Complete Single Malt Whisky Distillation System

II. Product Introduction of 6000L Complete Single Malt Whisky Distillation System

Part 1: Malt Handling Unit

* Responsible for receiving, cleaning, and storing malted barley.

* Equipped with conveyors, sieves, and storage silos to ensure a consistent supply of clean malt for the brewing process.

* Facilitates automated transfer of malt to the mashing unit, reducing manual labor and minimizing contamination.

Part 2: Mashing Unit

* Performs the conversion of starches in malted barley into fermentable sugars.

* Includes mash tuns with precise temperature control, agitators, and heating systems.

* Ensures uniform extraction of sugars for optimal fermentation performance.

Part 3: Fermentation Unit

* Converts the sugar-rich wort into alcohol using yeast.

* Consists of fermentation tanks (washbacks) with temperature control, aeration, and agitation systems.

* Designed to produce consistent wash with desired alcohol content and flavor profile.

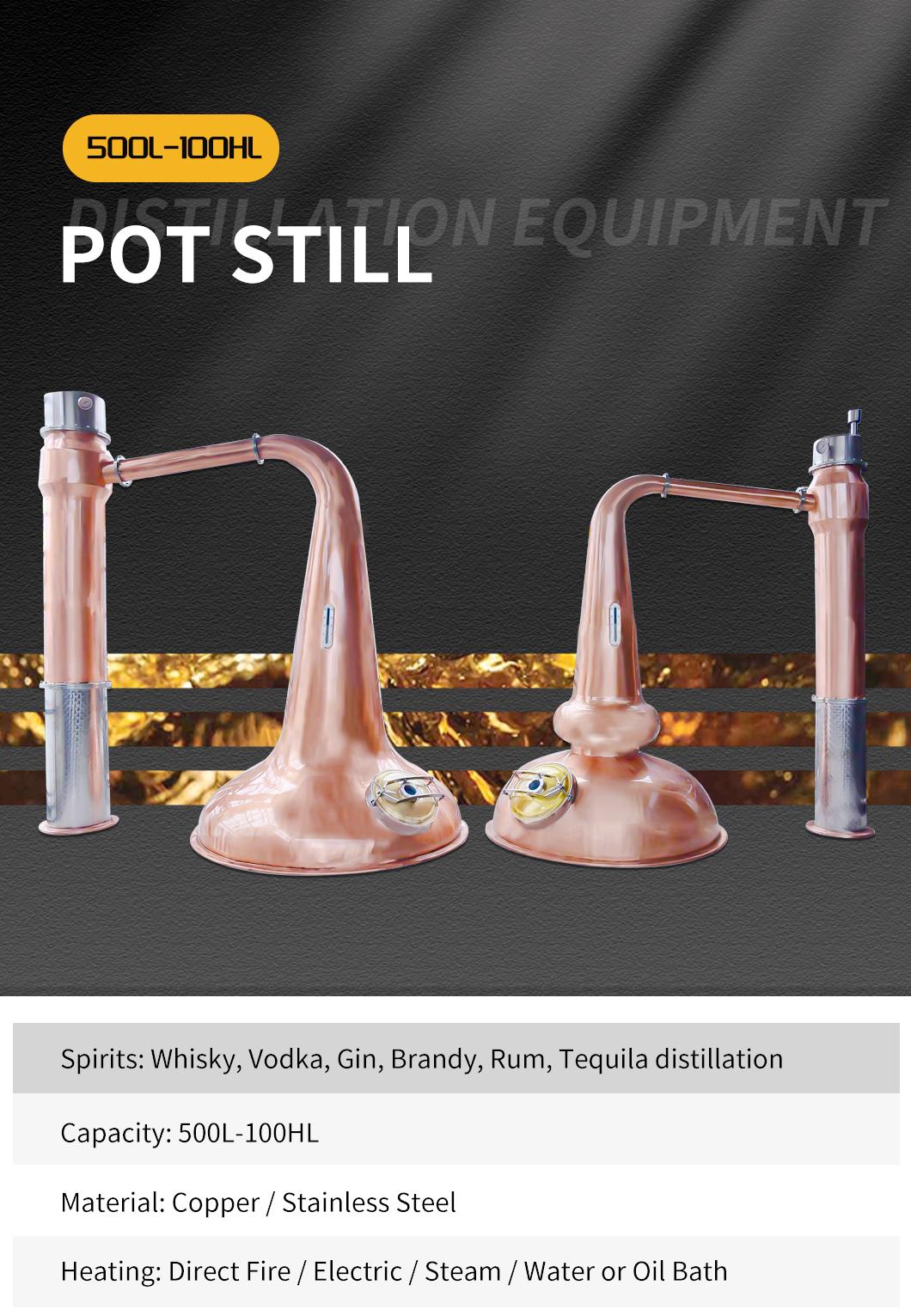

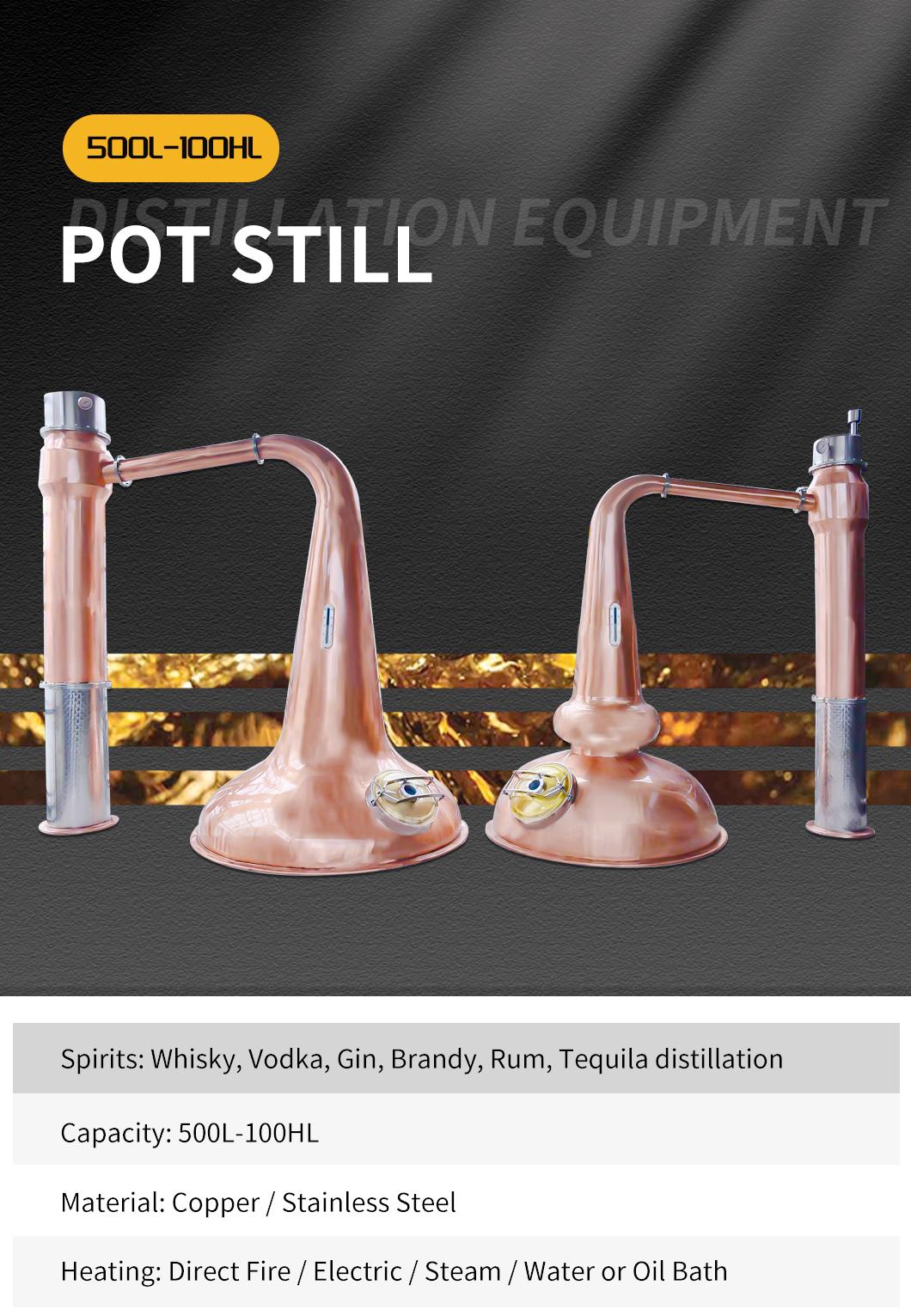

Part 4: Distillation Unit

* Conducts the separation of alcohol from the wash through distillation.

* Includes copper pot stills or distillation columns for single malt whisky, as well as condensers for vapor condensation.

* Allows precise control over spirit cuts (heads, hearts, tails) to ensure flavor integrity and quality.

Part 5: Spirit Store Unit

* Temporarily stores distilled whisky before aging or further processing.

* Equipped with temperature-controlled tanks and spirit safes to maintain purity and monitor alcohol strength.

Part 6: Glycol Chilling Unit

* Provides precise cooling for fermentation and distillation processes.

* Circulates chilled glycol to control temperatures in tanks, mash tuns, and condensers.

* Ensures optimal yeast activity and prevents overheating during distillation.

Part 7: Distillery Control Unit

* Centralized control system for monitoring and automating the entire distillation process.

* Includes sensors, PLCs, and HMI screens to track temperature, flow, and alcohol content in real time.

* Enhances operational efficiency, safety, and consistency of whisky production.

Part 8: CIP (Clean-in-Place) Unit

* Enables automatic cleaning of tanks, pipes, and equipment without disassembly.

* Ensures hygiene standards are met, reducing the risk of contamination and saving labor.

Part 9: Steam Supply Unit

* Provides reliable steam for heating mash tuns, distillation units, and other process needs.

* Includes steam generators or boilers with safety valves and pressure control.

* Ensures stable and energy-efficient operation throughout the distillery.

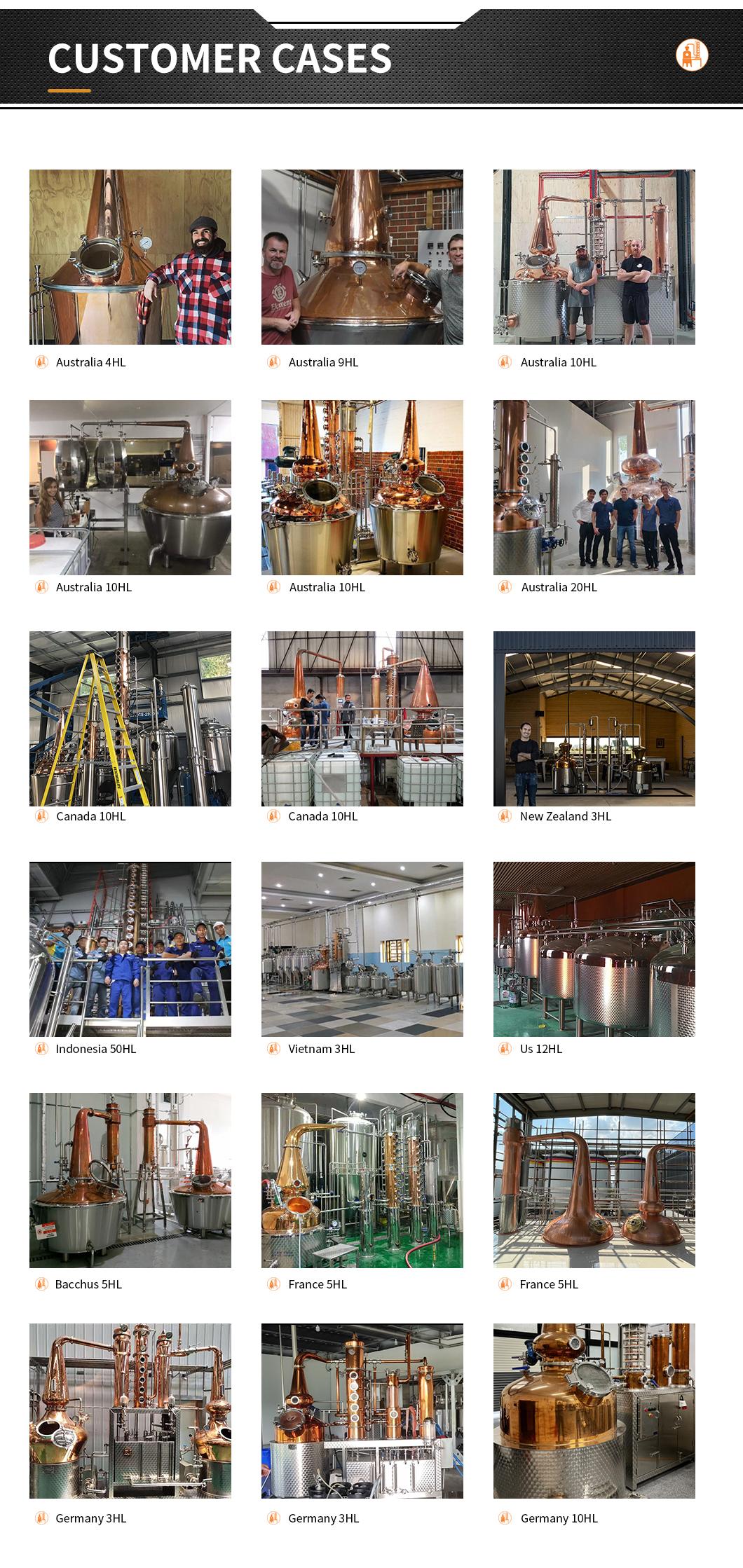

IV. Tiantai Complete Single Malt Whisky Distillation System

With Tiantai’s Complete Single Malt Whisky Distillation System, you can craft premium, flavorful single malt whisky with efficiency, precision, and consistency. From malt handling to fermentation, distillation, and aging, every unit is designed to ensure superior quality and operational reliability.

Take your distillery to the next level—contact us today for a personalized consultation and quotation, and start producing exceptional single malt whisky that stands out in the market.

Vicky

Email: [email protected]

Single Malt Whisky is a premium spirit made exclusively from malted barley at a single distillery, using traditional distillation methods. Renowned for its rich, complex flavors and smooth character, each batch reflects the unique influence of the distillery’s location, water source, and aging in oak casks. Connoisseurs and whisky enthusiasts can enjoy delicate notes of malt, vanilla, fruit, and subtle smoke, offering a refined and memorable tasting experience.

To help distillers craft high-quality single malt whisky, Tiantai Distillation System is designed for both craft and commercial distilleries, combining traditional craftsmanship with modern technology. The distillation system includes miller, mash/lauter tun, fermentation tanks, and copper pot stills or distillation columns, equipped with premium condensers and spirit collection devices to ensure optimal alcohol purity and flavor retention. Whether for small-batch or large-scale production, Tiantai distilling equipment enables distillers to consistently produce single malt whisky with unique character and exceptional quality.

Here, let us talk about 6000L Complete Single Malt Whisky Distillation System in details.

II. Key Configuration of 6000L Complete Single Malt Whisky Distillation System

| Part 1: Malt Handling Unit |

* Double Roller Malt Mill * Flexible Auger Conveyor * 4000L Grist Hopper * Malt Handling Control Panel |

| Part 2: Mashing Unit |

* 6000L Mash Lauter Tun * 6000L Wort Receiver * 12000L Hot Water Tank |

| Part 3: Fermentation Unit | 6000L Fermentation Tanks |

| Part 4: Distillation Unit |

* 6000L Copper Wash Still * 4000L Copper Spirit Still |

| Part 5: Spirit Store Unit |

* 4000L Low Spirit Receiver

* 3000L Head & Tail Receiver

* 2500L Heart Spirit Receiver

|

| Part 6: Glycol Chilling Unit |

Glycol Chiller + Cold Water Tank

|

| Part 7: Distillery Control Unit | Distillery Instrument Control Panel |

| Part 8: CIP Unit | Two-Tank Fixed CIP Station |

| Part 9: Steam Supply Unit | 700kg/hr Gas Powered Steam Generator |

II. Product Introduction of 6000L Complete Single Malt Whisky Distillation System

Part 1: Malt Handling Unit

* Responsible for receiving, cleaning, and storing malted barley.

* Equipped with conveyors, sieves, and storage silos to ensure a consistent supply of clean malt for the brewing process.

* Facilitates automated transfer of malt to the mashing unit, reducing manual labor and minimizing contamination.

Part 2: Mashing Unit

* Performs the conversion of starches in malted barley into fermentable sugars.

* Includes mash tuns with precise temperature control, agitators, and heating systems.

* Ensures uniform extraction of sugars for optimal fermentation performance.

Part 3: Fermentation Unit

* Converts the sugar-rich wort into alcohol using yeast.

* Consists of fermentation tanks (washbacks) with temperature control, aeration, and agitation systems.

* Designed to produce consistent wash with desired alcohol content and flavor profile.

Part 4: Distillation Unit

* Conducts the separation of alcohol from the wash through distillation.

* Includes copper pot stills or distillation columns for single malt whisky, as well as condensers for vapor condensation.

* Allows precise control over spirit cuts (heads, hearts, tails) to ensure flavor integrity and quality.

Part 5: Spirit Store Unit

* Temporarily stores distilled whisky before aging or further processing.

* Equipped with temperature-controlled tanks and spirit safes to maintain purity and monitor alcohol strength.

Part 6: Glycol Chilling Unit

* Provides precise cooling for fermentation and distillation processes.

* Circulates chilled glycol to control temperatures in tanks, mash tuns, and condensers.

* Ensures optimal yeast activity and prevents overheating during distillation.

Part 7: Distillery Control Unit

* Centralized control system for monitoring and automating the entire distillation process.

* Includes sensors, PLCs, and HMI screens to track temperature, flow, and alcohol content in real time.

* Enhances operational efficiency, safety, and consistency of whisky production.

Part 8: CIP (Clean-in-Place) Unit

* Enables automatic cleaning of tanks, pipes, and equipment without disassembly.

* Ensures hygiene standards are met, reducing the risk of contamination and saving labor.

Part 9: Steam Supply Unit

* Provides reliable steam for heating mash tuns, distillation units, and other process needs.

* Includes steam generators or boilers with safety valves and pressure control.

* Ensures stable and energy-efficient operation throughout the distillery.

IV. Tiantai Complete Single Malt Whisky Distillation System

With Tiantai’s Complete Single Malt Whisky Distillation System, you can craft premium, flavorful single malt whisky with efficiency, precision, and consistency. From malt handling to fermentation, distillation, and aging, every unit is designed to ensure superior quality and operational reliability.

Take your distillery to the next level—contact us today for a personalized consultation and quotation, and start producing exceptional single malt whisky that stands out in the market.

Vicky

Email: [email protected]