100L Complete Grain Whisky Distillery Equipment

- Jan 19, 2026

- 200

- tiantai

I. General introduction of 100L Complete Grain Whisky Distillery Equipment

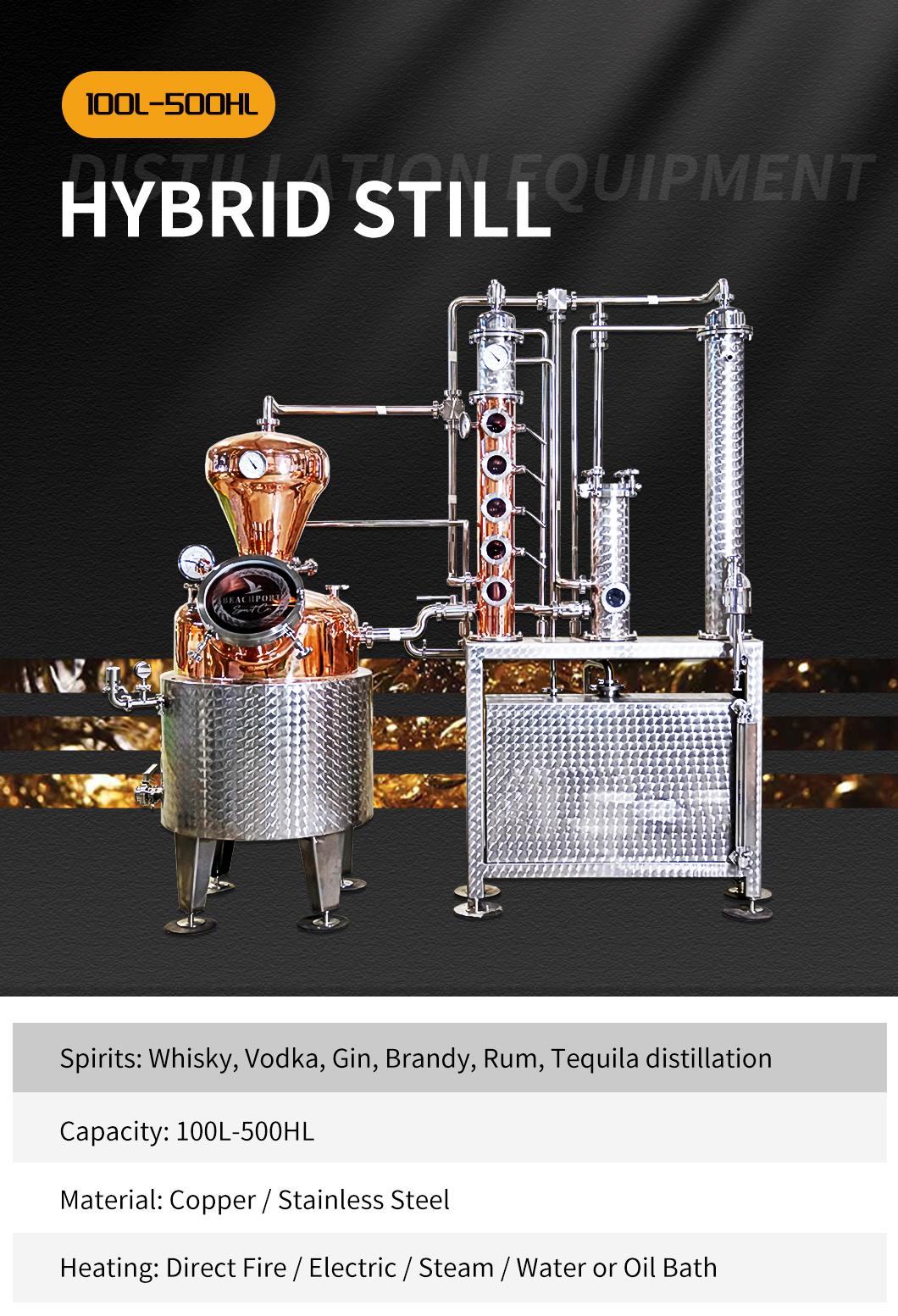

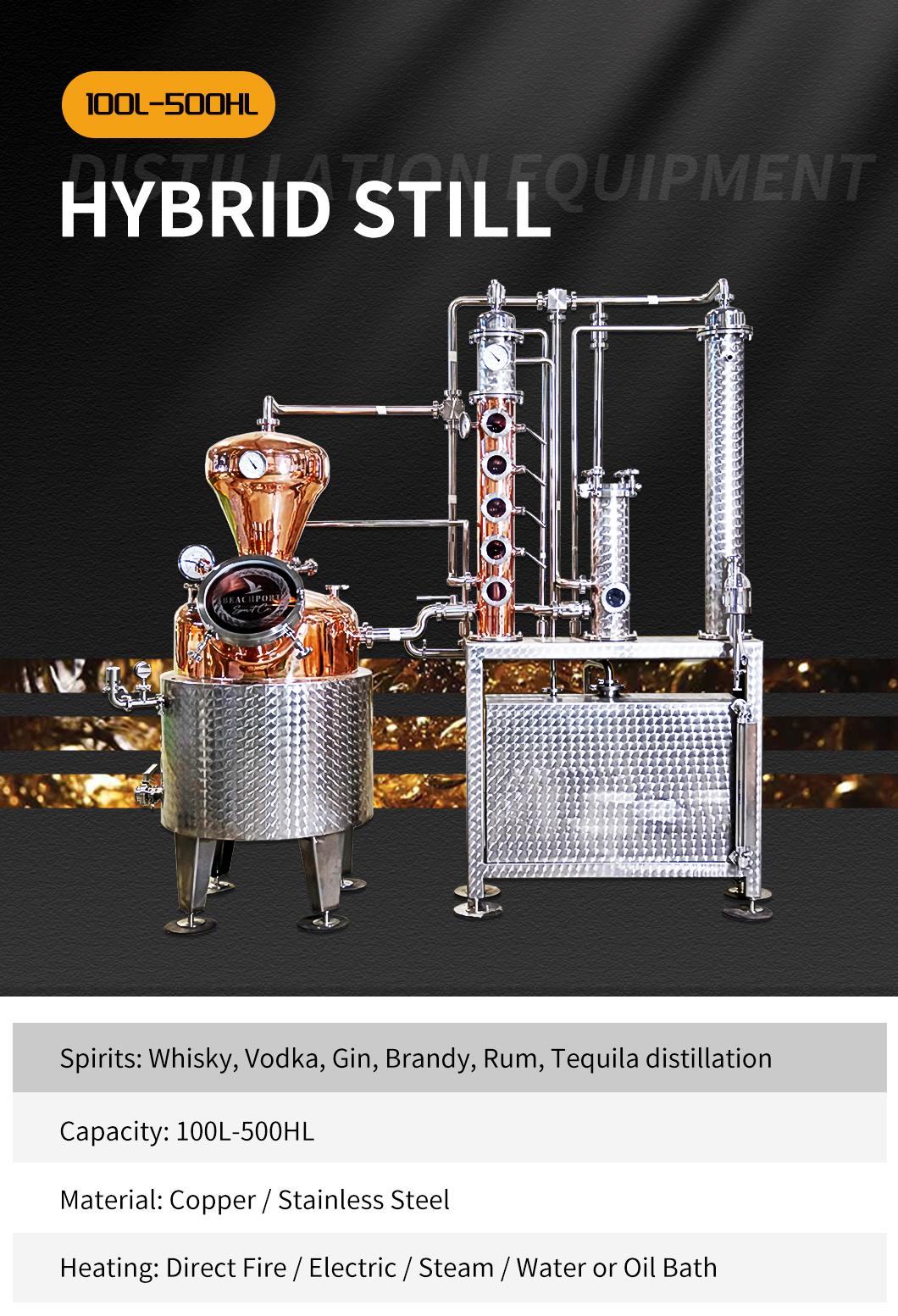

The 100L Complete Grain Whisky Distillery Equipment is specially designed for craft whisky production, pilot-scale distilling, and product development. With a capacity of 100 liters per batch, this distillery system offers an ideal balance of traditional craftsmanship and modern technology, making it suitable for small commercial distilleries, laboratories, and educational purposes.

The distillery equipment is constructed from SUS304 stainless steel combined with red copper components for the pot still, onion head, and rectification column. This ensures durability, easy cleaning, and excellent spirit quality by enhancing flavor during the distillation process.

The complete distillery system includes a grain miller, brewhouse for mashing and lautering, fermentation tanks with cooling jackets, a copper pot still with rectification column, condenser, parrot for alcohol measurement, glycol cooling system, and CIP unit. A manual control system is standard, with semi-automatic or PLC automation available as options.

Heating can be provided by electric elements or steam, depending on your preference. Compact in design yet complete in function, the 100L distillery system is easy to operate, clean, and maintain, while meeting professional standards of safety and sanitary.

This distillery equipment is ideal for producing authentic grain whisky with stable quality, and it can also be adapted for other spirits such as rum, gin, or brandy.

II. Speification of 100L Complete Grain Whisky Distillery Equipment

(1).jpg)

Tiantai Brewtech is a leading manufacturer and turnkey solution provider for distillery, brewery, winery and other beverage factory worldwide. With years of experience in research, design, manufacturing, and installation, Tiantai specializes in producing high-quality equipment for spirits, beer, wine, kombucha, and fruit wine.

Our company offers a full range of turnkey solutions, including brewhouses, fermentation tanks, distillation systems, cooling and glycol systems, CIP cleaning units, and packaging lines. Tiantai’s equipment is made from food-grade stainless steel, designed for durability, hygiene, and energy efficiency, and can be fully customized to meet each client’s capacity, beer style, or beverage type.

Tiantai has built a strong reputation in international markets, including Japan, Europe, North America, and Asia, for providing reliable, efficient, and innovative brewing solutions. Beyond equipment supply, the company delivers comprehensive project support, including layout design, installation supervision, operator training, and after-sales service, ensuring customers achieve stable operation and high-quality production.

Committed to innovation, quality, and customer satisfaction, Tiantai continues to expand its global presence, helping breweries and beverage producers of all sizes create outstanding products and achieve long-term success.

For more details, kindly contact us to get your proposal.

Derrick

Sales Manager

[email protected]

The 100L Complete Grain Whisky Distillery Equipment is specially designed for craft whisky production, pilot-scale distilling, and product development. With a capacity of 100 liters per batch, this distillery system offers an ideal balance of traditional craftsmanship and modern technology, making it suitable for small commercial distilleries, laboratories, and educational purposes.

The distillery equipment is constructed from SUS304 stainless steel combined with red copper components for the pot still, onion head, and rectification column. This ensures durability, easy cleaning, and excellent spirit quality by enhancing flavor during the distillation process.

The complete distillery system includes a grain miller, brewhouse for mashing and lautering, fermentation tanks with cooling jackets, a copper pot still with rectification column, condenser, parrot for alcohol measurement, glycol cooling system, and CIP unit. A manual control system is standard, with semi-automatic or PLC automation available as options.

Heating can be provided by electric elements or steam, depending on your preference. Compact in design yet complete in function, the 100L distillery system is easy to operate, clean, and maintain, while meeting professional standards of safety and sanitary.

This distillery equipment is ideal for producing authentic grain whisky with stable quality, and it can also be adapted for other spirits such as rum, gin, or brandy.

II. Speification of 100L Complete Grain Whisky Distillery Equipment

| System | Specification |

| Capacity | 100L per batch |

| Application | Small-batch grain whisky production, pilot testing, craft distilling |

| Material | SUS304 stainless steel + red copper (pot still, helmet, rectification parts) |

| Heating Method | Electric or steam heating (optional) |

| Milling System |

roller grain miller; 50–100 kg/hr capacity; Carbon steel or SUS304 with food-grade surface; Crushed grain for mashing |

| Brewhouse System |

Mash tun Capacity for 100L Mash Steam jacket or electric heating; manway, thermowell, CIP spray ball |

| Fermentation System |

SUS304 fermentation tanks with glycol jacket; 100/200L volume + headspace; PU insulation 50–80mm; PRV, sample valve, racking arm, CIP arm |

| Distillation System |

Copper pot still with onion head; Rectification column (copper/SUS304) with bubble plates/trays; Dephlegmator for higher ABV; Shell-and-tube or coil condenser; Parrot with alcohol meter + collection vessel |

| Cooling / Glycol System |

Compact glycol chiller sized for 50–100L tanks; SUS304 insulated glycol tank; Glycol circulation pump; Pre-insulated glycol piping |

| CIP System |

Small 2-tank CIP unit (alkali + acid); SUS304 stainless steel; Electric heating for caustic tank; CIP pump with spray balls |

| Control System |

Manual valves (standard), semi-automatic or PLC touchscreen optional; Monitoring of temperature, pump operation, heater control; |

(1).jpg)

Tiantai Brewtech is a leading manufacturer and turnkey solution provider for distillery, brewery, winery and other beverage factory worldwide. With years of experience in research, design, manufacturing, and installation, Tiantai specializes in producing high-quality equipment for spirits, beer, wine, kombucha, and fruit wine.

Our company offers a full range of turnkey solutions, including brewhouses, fermentation tanks, distillation systems, cooling and glycol systems, CIP cleaning units, and packaging lines. Tiantai’s equipment is made from food-grade stainless steel, designed for durability, hygiene, and energy efficiency, and can be fully customized to meet each client’s capacity, beer style, or beverage type.

Tiantai has built a strong reputation in international markets, including Japan, Europe, North America, and Asia, for providing reliable, efficient, and innovative brewing solutions. Beyond equipment supply, the company delivers comprehensive project support, including layout design, installation supervision, operator training, and after-sales service, ensuring customers achieve stable operation and high-quality production.

Committed to innovation, quality, and customer satisfaction, Tiantai continues to expand its global presence, helping breweries and beverage producers of all sizes create outstanding products and achieve long-term success.

For more details, kindly contact us to get your proposal.

Derrick

Sales Manager

[email protected]