25000L/Day Ginger Juice Process Machine

- May 19, 2025

- 131

- tiantai

1) Brief Introduction of 25000L/Day Ginger Juice Process Machine

Ginger Juice, such as traditional ginger beer or sparkling tonics, are made using fresh ginger, sugar, and natural fermentation. The brewing process usually involves boiling the ingredients, cooling the mixture, and fermenting it with yeast to create a naturally fizzy, flavorful beverage. These ginger juice are growing in popularity thanks to their refreshing taste and natural appeal.

At Tiantai Brewtech, we provide complete processing machine for ginger juice production — from ginger washing, crushing, boiling and fermentation tanks to cooling systems, CIP units, and bottling machines. Whether you're starting a small craft line or scaling up, we can help design and supply the right ginger drink production solution for your turnkey ginger juice plant.

Here, let us talk about 25000L/Day Ginger Juice Process Machine in details.

.jpg)

2) General Configuration of 25000L/Day Ginger Juice Process Machine

| Ginger Washer | 2000-2500kg/hr |

| Conveyor Belt | from Ginger Washer to Ginger Crusher |

| Ginger Crusher | 3000-4000kg/hr |

| Conveyor Belt | From Ginger Crusher to Brewhouse |

| Brewhouse Unit | 5000L Kettle Tun |

| 5000L Hot Water Tank | |

| Valves, Pumps, Heat Exchanger, Working Platform, Various Sensors | |

| Fermentation Unit | 8 sets 25000L Fermentation Tank |

| Filling Unit | Automatic Bottling Line and Canning Line |

| Glycol Chilling System | 1 x 5000L Glycol Water Tank |

| 2 x 20HP Glycol Chiller | |

| Glycol Water Pipeline | |

| Electric Control Unit | Instrumental Control Panel or PLC with Touch Screen |

| CIP Unit | 1000L Three Tank, Caustic Tank, Acid Tank, Sterilize Tank |

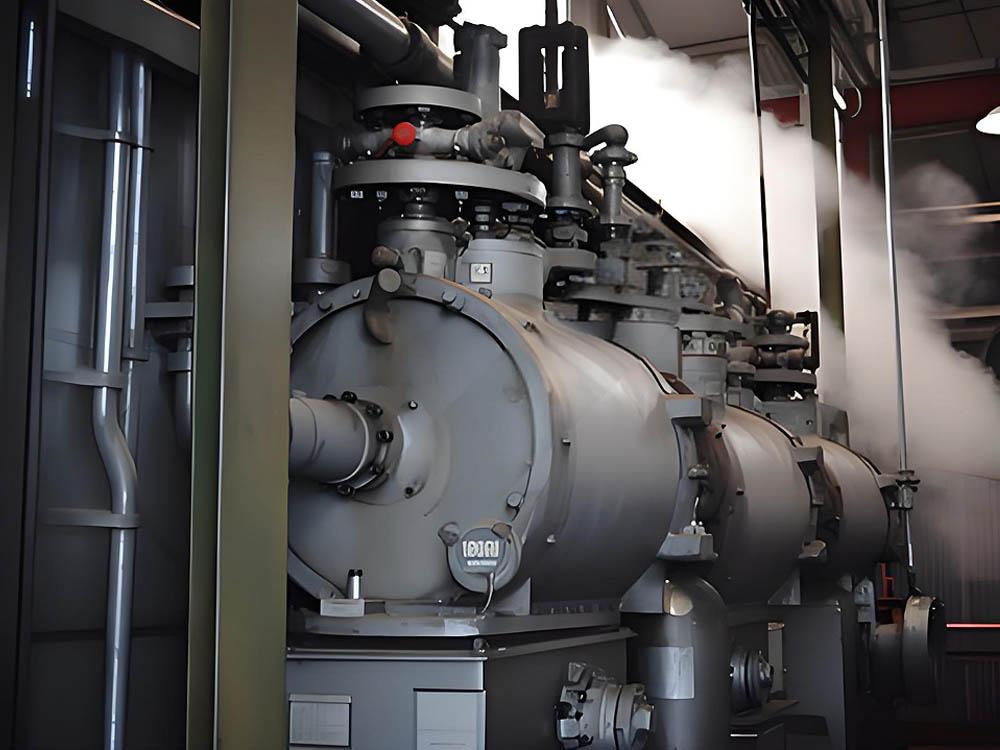

| Steam Supply Unit | 1000kg/hr Steam Boiler, Steam Pipeline and Steam Fittings |

| Auxiliary Machine | Filter, Pasteurizer, Air Compressor, Water Treatment System etc |

3) Technical Basis of 25000L/Day Ginger Juice Process Machine

| Ingredients |

Fresh ginger root – the key ingredient for flavor and aroma

Sugar – typically white sugar, brown sugar, or cane sugar

Water – clean, filtered brewing water

Lemon juice – for acidity and freshness (optional)

Spices – such as cloves, cinnamon, or chili (optional, regional variations)

Fruit peels – e.g. pineapple peel or orange zest (optional, for complexity)

Yeast – for fermentation (optional, if producing a fermented ginger drink)

Natural flavorings or herbs – such as mint, hibiscus, or lemongrass (optional)

|

| Brew Length ( Cast Cold Out) | 5000L |

| Brew Batches per day | 1-5 batches |

| No. of working days | 300 |

| Cold wort collection per day | 25000L |

| Pasteurization | Yes |

| Evaporation Rate: | 8% - 10% |

| Voltage Supply | 400V, 3 Phases,50HZ AC, 24V DC or customized |

| Water Supply Pressure | 2 - 6 bar |

| Steam Working Pressure | 2 bar |

| Air Source Pressure | 2 - 8 bar |

| Brewery Expanding | Available |

At Tiantai Brewtech, we offer complete solutions for ginger juice process machine. Whether you’re producing traditional African ginger juice or launching a commercial ginger juice line, our machine is designed for efficiency, hygiene, and consistent quality. Contact us today for a tailored quote and technical support!

.jpg)