Choosing the Right Brewhouse Platform for Your Brewery Equipment

- May 19, 2025

- 56

- tiantai

Choosing the Right Brewhouse Platform for Your Brewery Equipment

When setting up a modern brewery, selecting the right brewhouse platform is a critical decision that directly impacts safety, workflow, and cleanliness.

Whether you're a small craft operation or a larger-scale commercial facility, the platform is the foundation—literally and figuratively—of your brewing operation. At the heart of this choice lies a few core materials: diamond plate, perforated plate, and grating. Each has its unique advantages and applications, and understanding these will help you make the best decision for your brewery.

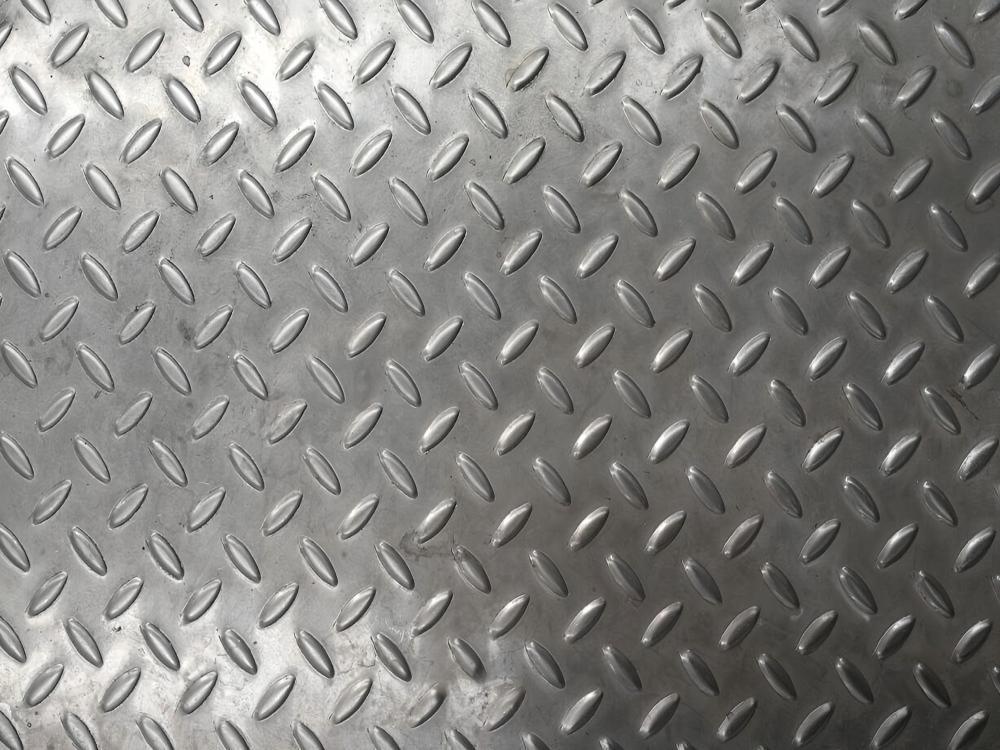

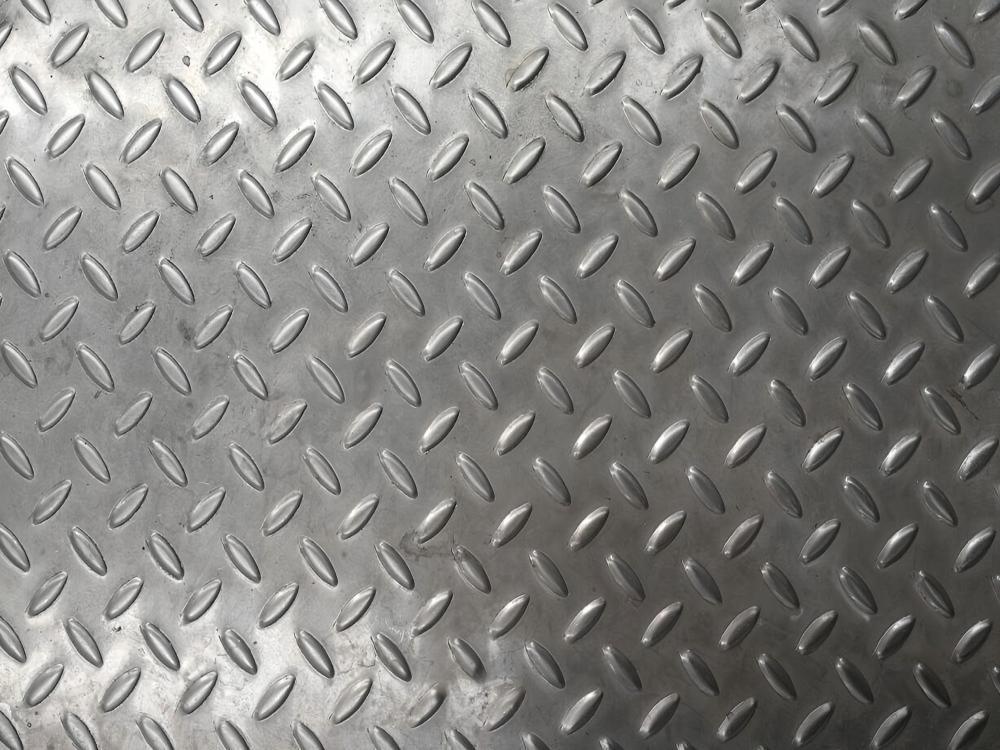

1. Diamond Plate: Rugged and Anti-Slip

One of the most popular choices for brewhouse platforms is the diamond plate, often made from stainless steel or aluminum.

As seen in the image above, the distinctive raised pattern creates a textured surface that provides excellent grip.

This anti-slip feature makes it ideal for wet brewing environments where spills are common.

Diamond plate is not only about safety—it’s also incredibly durable.

It withstands heavy foot traffic, frequent cleaning, and the daily wear and tear typical in a working brewery.

Additionally, its solid structure offers high load-bearing capacity, which is crucial for safely supporting brewers, tools, and brewing vessels.

For breweries looking for a low-maintenance, long-lasting, and functional brewhouse platform, diamond plate is a tried-and-true solution.

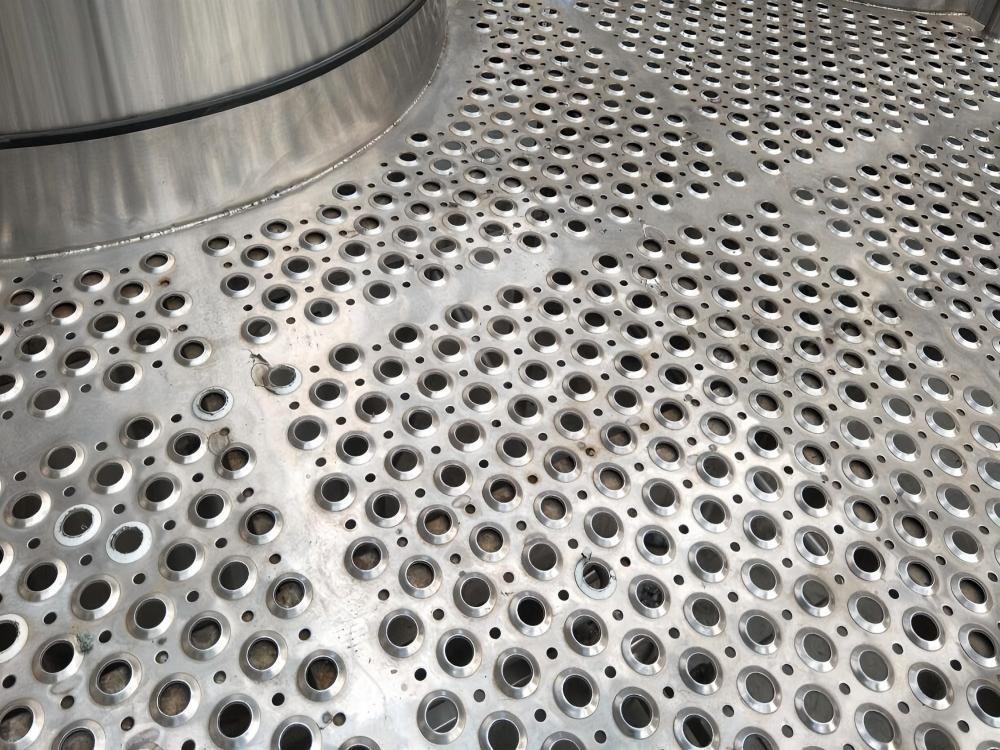

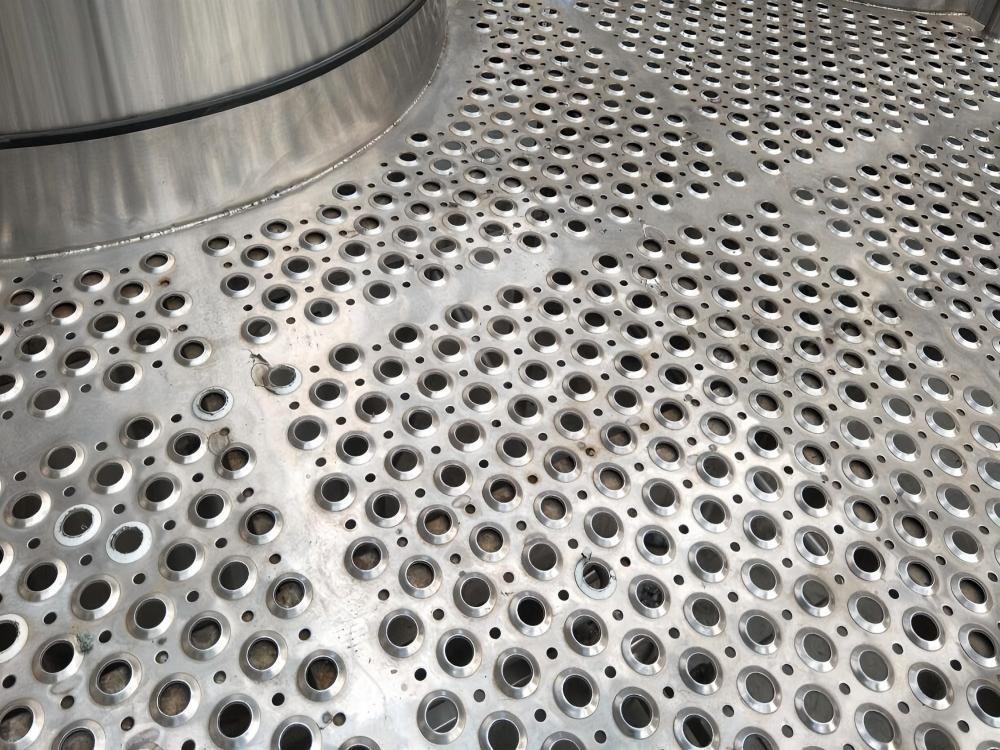

2. Perforated Plate (Fish-Eye Plate): Drainage and Airflow

The perforated plate, or fish-eye plate, is another common option for brewery equipment platforms.

Characterized by evenly spaced holes—sometimes with raised rims—this material is particularly effective at promoting drainage and ventilation.

Water and liquid spills can easily pass through the perforations, reducing the risk of slipping and helping maintain a cleaner work environment.

This type of platform is especially useful in breweries with frequent cleaning schedules or where sanitation is a top priority.

Besides drainage, the open surface of perforated plates allows better airflow underneath the platform, which can help prevent mold or bacterial buildup.

This makes it a popular choice in regions with higher humidity or in breweries that prioritize hygiene as part of their daily operation.

3. Grating: Strength and Cleanability

There is no one-size-fits-all when it comes to brewhouse platforms.

Each brewery is unique, and the platform must match the scale, layout, and production capacity of your setup.

At our facility, we tailor brewery equipment to fit your specific brewing ambitions—whether you're opening your first taproom or expanding a regional craft brand.

Not sure what works best for you? Let us help.

Just share your estimated production scale and layout preference, and we’ll guide you to the ideal configuration.

Start Strong with the Right Brewhouse Platform

Choosing the right brewhouse platform ensures a smoother, safer, and more efficient brewing process.

Whether you're leaning toward diamond plate for its rugged texture, perforated plate for better drainage, or heavy-duty grating for industrial-scale support, we offer brewery equipment solutions that can be fully customized to meet your vision.

Reach out today to explore our full platform options and see how we can support your brewery with reliable, purpose-built equipment.

Edited by Amanda

Sales manager | Tiantai beer equipment

Email: [email protected]

When setting up a modern brewery, selecting the right brewhouse platform is a critical decision that directly impacts safety, workflow, and cleanliness.

Whether you're a small craft operation or a larger-scale commercial facility, the platform is the foundation—literally and figuratively—of your brewing operation. At the heart of this choice lies a few core materials: diamond plate, perforated plate, and grating. Each has its unique advantages and applications, and understanding these will help you make the best decision for your brewery.

1. Diamond Plate: Rugged and Anti-Slip

One of the most popular choices for brewhouse platforms is the diamond plate, often made from stainless steel or aluminum.

As seen in the image above, the distinctive raised pattern creates a textured surface that provides excellent grip.

This anti-slip feature makes it ideal for wet brewing environments where spills are common.

Diamond plate is not only about safety—it’s also incredibly durable.

It withstands heavy foot traffic, frequent cleaning, and the daily wear and tear typical in a working brewery.

Additionally, its solid structure offers high load-bearing capacity, which is crucial for safely supporting brewers, tools, and brewing vessels.

For breweries looking for a low-maintenance, long-lasting, and functional brewhouse platform, diamond plate is a tried-and-true solution.

2. Perforated Plate (Fish-Eye Plate): Drainage and Airflow

The perforated plate, or fish-eye plate, is another common option for brewery equipment platforms.

Characterized by evenly spaced holes—sometimes with raised rims—this material is particularly effective at promoting drainage and ventilation.

Water and liquid spills can easily pass through the perforations, reducing the risk of slipping and helping maintain a cleaner work environment.

This type of platform is especially useful in breweries with frequent cleaning schedules or where sanitation is a top priority.

Besides drainage, the open surface of perforated plates allows better airflow underneath the platform, which can help prevent mold or bacterial buildup.

This makes it a popular choice in regions with higher humidity or in breweries that prioritize hygiene as part of their daily operation.

3. Grating: Strength and Cleanability

Grating stands out as the most robust option among the three.

Composed of intersecting metal bars, this material offers exceptional load-bearing performance—perfect for larger-scale operations or breweries where equipment and foot traffic are heavy.

Composed of intersecting metal bars, this material offers exceptional load-bearing performance—perfect for larger-scale operations or breweries where equipment and foot traffic are heavy.

Grating also provides maximum drainage and airflow. Any liquid spills immediately pass through, keeping surfaces dry and safe.

Additionally, the open structure prevents the buildup of dirt or debris, making cleaning fast and effective.

If your brewery equipment setup demands both strength and hygiene, grating is often the top recommendation.

Additionally, the open structure prevents the buildup of dirt or debris, making cleaning fast and effective.

If your brewery equipment setup demands both strength and hygiene, grating is often the top recommendation.

There is no one-size-fits-all when it comes to brewhouse platforms.

Each brewery is unique, and the platform must match the scale, layout, and production capacity of your setup.

At our facility, we tailor brewery equipment to fit your specific brewing ambitions—whether you're opening your first taproom or expanding a regional craft brand.

Not sure what works best for you? Let us help.

Just share your estimated production scale and layout preference, and we’ll guide you to the ideal configuration.

Start Strong with the Right Brewhouse Platform

Choosing the right brewhouse platform ensures a smoother, safer, and more efficient brewing process.

Whether you're leaning toward diamond plate for its rugged texture, perforated plate for better drainage, or heavy-duty grating for industrial-scale support, we offer brewery equipment solutions that can be fully customized to meet your vision.

Reach out today to explore our full platform options and see how we can support your brewery with reliable, purpose-built equipment.

Edited by Amanda

Sales manager | Tiantai beer equipment

Email: [email protected]